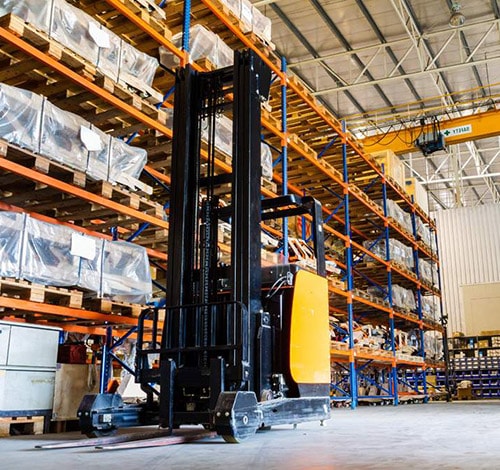

BUY INDUSTRIAL EQUIPMENT

Once you decide to expand your fleet, it is time to decide whether to buy or rent the machine. However, if you are planning on purchasing the machine, you must decide whether to purchase used industrial parts or new machine.

It is affordable to purchase a used machine. That is why it is much cheaper to rent a machine than to buy a new one. However, if you are buying a used machine for the first time, you must take the necessary precautions since it is risky to get a good used machine. You can lose your investment if you buy the wrong used machine.

If you want to avoid the risks and make sure you are buying a quality used machine, then read on to learn how to buy the right used machine for your company:

How to Purchase a Used Machine

Check the financial history of the used machine. Make sure the used machine has been paid off to ensure the title will transfer. Additionally, make sure there are no liens against the used machine.

Check the used machine’s total operating hours just the way you check a used car’s mileage.

Check the maintenance reports and schedule of the used machine. It is better to choose a well-maintained used machine. Make sure the previous owner fixed problems quickly and correctly.

Check the fluids of the used machine, such as coolant, hydraulic fluid, transmission fluid, and engine oil. If the fluids are dirty or low, it can mean the previous owner did not properly maintain the machine.

Check for damages. It is common for heavy machinery to wear and tear over time. However, you must check for problems, such as rusting, hairline cracks, and more, since it is expensive to repair them. If you buy a used machine with these problems, you might spend more money on repairs.

Inspect the transmission and engine to make sure there are no unusual emissions and weird sounds.

Examine the used machine’s chassis. And check the hydraulic components, rams, pumps, and hoses for leaks and damages.

Check the tires and tracks of the used machine for bubbles and cracks. Make sure there is no uneven wear on the tread gauge of the tires and there are no missing bolts and tracks on the track machine.

Check the welding in different places, such as loader arms, buckets, and backhoe since they indicate repaired breaks. If there is welding, just know the welds are not strong like the original before breaking.

Test the controls of the used machine properly, such as seat adjustments, safety features, dashboard features, steering, sticks, pedals, etc.

Purchase a used machine from a trustworthy dealer. Therefore, check the service agreements, warranties, guarantees, maintenance capabilities, experience, online testimonials or reviews, reputation, and the website of the dealer before buying their used machine.

Compare the operating hours, age, and the cost of the used machine to the cost of buying a new machine. Machines usually lose 20% to 40% of their value in their first year of use. However, if the owner maintains and services their machine, it can maintain its value for several years. Therefore, you need to check the technology of the used machine since technology changes rapidly nowadays. Make sure you can work with the technology of the used machine.